Hardrock Tunnel Boring Machines: The Ultimate Guide

The construction of tunnels through hard rock formations, such as granite, gneiss, and quartzite, presents unique challenges that require specialized machinery. Hardrock Tunnel Boring Machines (TBM) are powerful and versatile pieces of equipment designed to excavate these challenging geological conditions, enabling the construction of tunnels for various purposes.

4.8 out of 5

| Language | : | English |

| File size | : | 12103 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 356 pages |

| Lending | : | Enabled |

Origins and Evolution of TBM

The concept of TBM originated in the 19th century when engineers sought to develop machines that could bore through rock faster and more efficiently. The first successful TBM was built in 1853 by a French engineer, Francois Coignet. This machine used rotating cutters to break down the rock, while a conveyor system removed the excavated material. Since then, TBM technology has evolved significantly, incorporating advancements in cutting tools, propulsion systems, and control systems.

Types of Hardrock TBM

There are several different types of Hardrock TBM, each suited to specific geological conditions and project requirements. The main types include:

- Single Shield TBM: These TBMs have a cylindrical shield that protects the excavation face and provides support to the tunnel as it is constructed.

- Double Shield TBM: Similar to Single Shield TBM, but with an additional outer shield that provides additional support and stability, especially in unstable ground conditions.

- Earth Pressure Balance TBM (EPB TBM): These TBMs use the excavated material to create a balance of pressure against the tunnel face, making them suitable for soft to medium-hard rock formations.

- Gripper TBM: These TBMs use grippers to anchor themselves against the tunnel walls, providing stability and allowing for high torque excavation in hard rock.

- Slurry TBM: These TBMs use a slurry of water and bentonite to lubricate the excavation process and remove the excavated material.

Components of a Hardrock TBM

A typical Hardrock TBM consists of the following major components:

- Cutterhead: The rotating front part of the TBM equipped with cutting tools that break down the rock.

- Shield: The cylindrical structure that protects the excavation face and provides support to the tunnel.

- Conveyor System: Removes the excavated material from the tunnel.

- Propulsion System: Moves the TBM forward through the rock.

- Control System: Monitors and controls the operation of the TBM, including cutterhead rotation, propulsion, and steering.

Applications of Hardrock TBM

Hardrock TBM are used in a wide range of applications, including:

- Tunnel Construction: For transportation, infrastructure, hydropower projects, and mining.

- Shaft Sinking: For access, ventilation, and service purposes in underground mines and infrastructure.

- Raise Boring: Creating vertical or inclined shafts for exploration, ventilation, and access.

Advantages of Hardrock TBM

Hardrock TBM offer several advantages over traditional drilling and blasting methods:

- Increased Efficiency: TBMs can excavate rock faster and more efficiently, reducing project timelines.

- Improved Safety: TBMs minimize the risk of accidents associated with drilling and blasting, providing a safer work environment.

- Reduced Environmental Impact: TBMs generate less noise and vibration than blasting, reducing the environmental impact of tunnel construction.

- Precise Excavation: TBMs can excavate tunnels with high precision, reducing the need for costly over-excavation and rework.

- Versatile Application: Hardrock TBMs can adapt to various geological conditions, allowing for use in a wide range of projects.

Challenges and Limitations

Despite their advantages, Hardrock TBM also face certain challenges and limitations:

- High Capital Cost: TBMs are expensive pieces of equipment, requiring significant investment for Free Download and operation.

- Complex Operation: Operating a TBM requires specialized expertise and training, which can be a limiting factor for some projects.

- Geological Constraints: While TBMs are designed for hard rock formations, they may encounter difficulties in extreme geological conditions, such as highly fractured or abrasive rock.

Hardrock Tunnel Boring Machines are remarkable feats of engineering that have revolutionized the construction of tunnels in challenging geological conditions. These machines have enabled the development of critical infrastructure, including transportation systems, hydropower projects, and mining operations, while also improving safety and reducing environmental impact. As technology continues to advance, Hardrock TBM will undoubtedly play an even more significant role in shaping the future of underground construction.

Image Credits

- Image Source 1

- Image Source 2

- Image Source 3

4.8 out of 5

| Language | : | English |

| File size | : | 12103 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 356 pages |

| Lending | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Michele Knight

Michele Knight Billy Porter

Billy Porter David G Andrews

David G Andrews Peter Gottschalk

Peter Gottschalk Dennis Broe

Dennis Broe Roger Nygard

Roger Nygard Col David J Giammona

Col David J Giammona Libby Hinsley

Libby Hinsley Carl Zetie

Carl Zetie Alan Mallach

Alan Mallach Andrea Mauro

Andrea Mauro Michael Eigen

Michael Eigen Richard Irvin

Richard Irvin Chiemi Souen

Chiemi Souen Semisi Pone

Semisi Pone Gail Parker

Gail Parker Bruce C Brown

Bruce C Brown Soulja Choc

Soulja Choc Wendy M Tietz

Wendy M Tietz Bill Brown

Bill Brown

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Dallas TurnerThe Dream Book Symbols for Self-Understanding: A Journey into the Uncharted...

Dallas TurnerThe Dream Book Symbols for Self-Understanding: A Journey into the Uncharted... Jeff FosterFollow ·15.3k

Jeff FosterFollow ·15.3k Stan WardFollow ·13.8k

Stan WardFollow ·13.8k Ralph TurnerFollow ·11.1k

Ralph TurnerFollow ·11.1k Francis TurnerFollow ·19.3k

Francis TurnerFollow ·19.3k Eli BlairFollow ·19.8k

Eli BlairFollow ·19.8k Arthur C. ClarkeFollow ·5.7k

Arthur C. ClarkeFollow ·5.7k George Bernard ShawFollow ·19.8k

George Bernard ShawFollow ·19.8k Mario BenedettiFollow ·11.4k

Mario BenedettiFollow ·11.4k

Henry Green

Henry GreenCorrosion and Its Consequences for Reinforced Concrete...

Corrosion is a major threat to reinforced...

James Gray

James GrayDiscover the Enigmatic World of Pascin in "Pascin Mega...

Immerse Yourself in the...

George R.R. Martin

George R.R. MartinUnlocking the Power of Nature: Delve into the Bioactive...

In a world increasingly...

Julian Powell

Julian PowellMaster the Art of Apple Watch App Development: A...

Unlock the Potential of Apple Watch Apps In...

Jaylen Mitchell

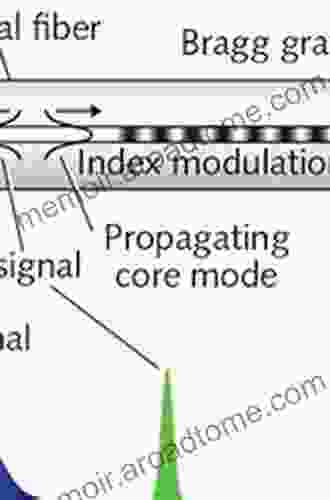

Jaylen MitchellPlastic Optical Fiber Sensors: A Comprehensive Guide to...

In the rapidly evolving landscape of...

Truman Capote

Truman CapoteUnlock the Secrets of Language Creation: Dive into...

The realm of computer science...

4.8 out of 5

| Language | : | English |

| File size | : | 12103 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 356 pages |

| Lending | : | Enabled |