Engineering Plasticity Theory and Applications in Metal Forming: A Comprehensive Guide

Engineering plasticity theory plays a crucial role in understanding and predicting the behavior of materials under load. It provides the foundation for designing and optimizing metal forming processes, ensuring the production of high-quality components. This comprehensive guide delves into the essential principles of engineering plasticity theory and its applications in metal forming, offering a valuable resource for engineers, researchers, and students in the field.

Theoretical Foundations

Plasticity theory is a branch of mechanics that deals with the permanent deformation of materials subjected to external forces. It provides a mathematical framework for quantifying material behavior and predicting its response to various loading conditions. This section covers the fundamental concepts of plasticity theory, including:

5 out of 5

| Language | : | English |

| File size | : | 51894 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 486 pages |

| Lending | : | Enabled |

- Stress and Strain Tensors: Describing the internal forces and deformations within a material.

- Yielding Criteria: Predicting the onset of plastic deformation and identifying the critical stress states that initiate yielding.

- Flow Rule: Characterizing the plastic flow behavior of materials and determining the direction and magnitude of plastic deformation.

- Hardening Laws: Representing the increase in material strength as a result of plastic deformation.

Applications in Metal Forming

Metal forming processes involve塑性变形of metal workpieces to achieve desired shapes and properties. Engineering plasticity theory provides a powerful tool for analyzing and optimizing these processes by predicting material flow, identifying potential defects, and optimizing process parameters. This section explores the applications of plasticity theory in various metal forming techniques, including:

- Sheet Metal Forming: Predicting the behavior of sheet metal under various forming operations, such as stamping, bending, and deep drawing.

- Bulk Metal Forming: Analyzing the deformation of bulk materials in processes like forging, rolling, and extrusion.

- Advanced Forming Techniques: Investigating the mechanics of unconventional forming methods, such as hydroforming, electromagnetic forming, and incremental forming.

Computational Methods

The advent of powerful computational tools has revolutionized the analysis of metal forming processes. Finite element analysis (FEA) and other numerical techniques enable the simulation of complex material behavior and process conditions, providing valuable insights into the deformation patterns, stress distributions, and forming loads. This section discusses the integration of computational methods with engineering plasticity theory, highlighting their role in:

- Process Optimization: Identifying optimal process parameters and minimizing defects through numerical simulations.

- Virtual Prototyping: Predicting product performance and refining designs before physical prototyping.

- Materials Characterization: Extracting material properties from experimental data using inverse methods.

Case Studies and Applications

To illustrate the practical applications of engineering plasticity theory in metal forming, this section presents real-world case studies and industrial examples. These case studies showcase how the theory has been successfully employed to:

- Improve Forming Accuracy: Optimizing sheet metal forming processes to reduce springback and improve dimensional accuracy.

- Enhance Formability: Identifying suitable materials and process conditions to enhance the formability of advanced materials.

- Prevent Defects: Analyzing forming processes to predict and prevent defects such as wrinkling, tearing, and fracture.

Future Directions

The field of engineering plasticity theory and its applications in metal forming continues to evolve, with ongoing research and advancements in both theoretical and computational aspects. This section discusses emerging trends and future directions in the field, including:

- Multiscale Modeling: Bridging different length scales to connect material microstructure with macroscopic forming behavior.

- Data-Driven Approaches: Utilizing machine learning and artificial intelligence to enhance material modeling and process optimization.

- Sustainable Manufacturing: Integrating plasticity theory with sustainability considerations to minimize environmental impact in metal forming.

Engineering plasticity theory plays a vital role in understanding and controlling the behavior of materials in metal forming processes. This comprehensive guide provides a thorough exploration of the theoretical foundations, applications, computational methods, and practical implications of plasticity theory. By mastering these concepts, engineers can optimize forming processes, improve product quality, and drive innovation in the metalworking industry.

5 out of 5

| Language | : | English |

| File size | : | 51894 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 486 pages |

| Lending | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Terry Ryan

Terry Ryan John Wimber

John Wimber John Lennox

John Lennox Eileen W Johnson

Eileen W Johnson Bobbie Brown

Bobbie Brown Me Ra Koh

Me Ra Koh Greg Stones

Greg Stones Allen Chankowsky

Allen Chankowsky Paul Holtham

Paul Holtham Bruce C Brown

Bruce C Brown Ken Ammi

Ken Ammi Alastair Humphreys

Alastair Humphreys Emerald Moon

Emerald Moon Trudi Entwistle

Trudi Entwistle Lauri Lebo

Lauri Lebo Andy Roman

Andy Roman Pyram King

Pyram King Susan Rowland

Susan Rowland David Feldman

David Feldman Ian M Philpott

Ian M Philpott

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

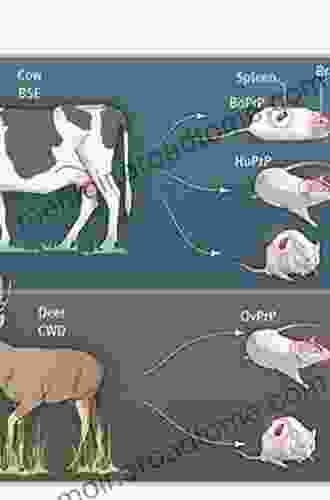

Robert BrowningUnveiling the Enigmatic World of Prions: A Comprehensive Guide to Prions in...

Robert BrowningUnveiling the Enigmatic World of Prions: A Comprehensive Guide to Prions in... Adam HayesFollow ·10.6k

Adam HayesFollow ·10.6k Jerome BlairFollow ·12.4k

Jerome BlairFollow ·12.4k Robin PowellFollow ·6.2k

Robin PowellFollow ·6.2k Rob FosterFollow ·13.3k

Rob FosterFollow ·13.3k Haruki MurakamiFollow ·2.9k

Haruki MurakamiFollow ·2.9k Ernest PowellFollow ·4.9k

Ernest PowellFollow ·4.9k Logan CoxFollow ·8.9k

Logan CoxFollow ·8.9k Ralph Waldo EmersonFollow ·6.6k

Ralph Waldo EmersonFollow ·6.6k

Henry Green

Henry GreenCorrosion and Its Consequences for Reinforced Concrete...

Corrosion is a major threat to reinforced...

James Gray

James GrayDiscover the Enigmatic World of Pascin in "Pascin Mega...

Immerse Yourself in the...

George R.R. Martin

George R.R. MartinUnlocking the Power of Nature: Delve into the Bioactive...

In a world increasingly...

Julian Powell

Julian PowellMaster the Art of Apple Watch App Development: A...

Unlock the Potential of Apple Watch Apps In...

Jaylen Mitchell

Jaylen MitchellPlastic Optical Fiber Sensors: A Comprehensive Guide to...

In the rapidly evolving landscape of...

Truman Capote

Truman CapoteUnlock the Secrets of Language Creation: Dive into...

The realm of computer science...

5 out of 5

| Language | : | English |

| File size | : | 51894 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 486 pages |

| Lending | : | Enabled |