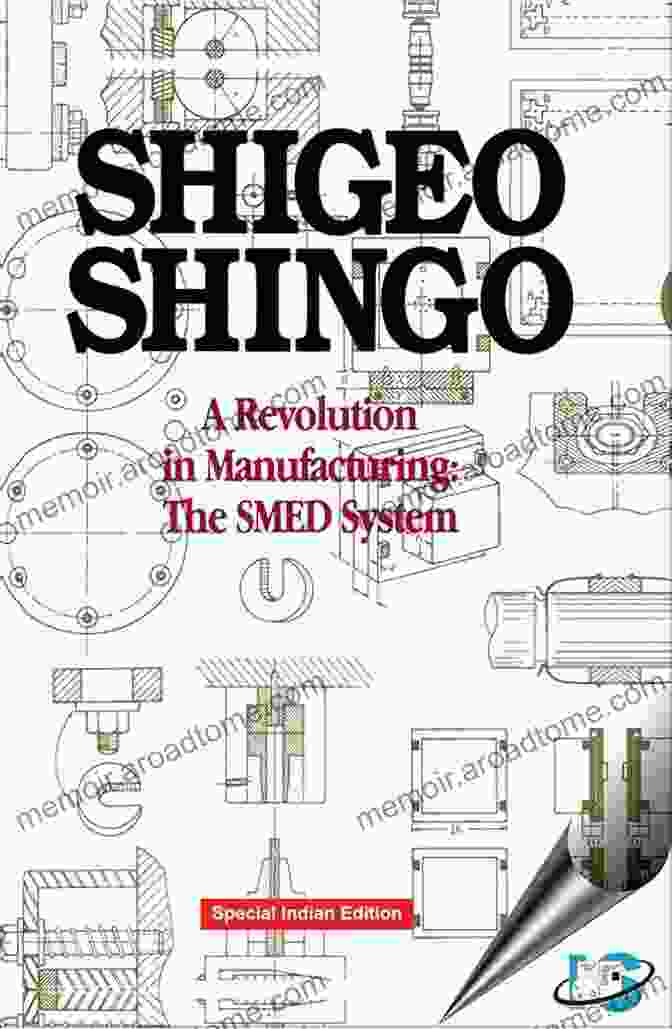

Revolution In Manufacturing: The SMED System

4.7 out of 5

| Language | : | English |

| File size | : | 15309 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 371 pages |

Unveiling the Revolutionary Approach to Enhance Productivity and Efficiency

In today's fiercely competitive manufacturing landscape, optimizing efficiency and productivity is paramount to success. The Single-Minute Exchange of Dies (SMED) system emerges as a game-changer, empowering manufacturers to dramatically reduce setup times and unlock unparalleled levels of productivity.

Developed by the legendary Toyota Production System, SMED is a systematic approach that breaks down setup processes into smaller, more manageable steps. By eliminating waste and streamlining operations, manufacturers can achieve setup times of less than 10 minutes, significantly boosting overall equipment effectiveness (OEE).

The Pillars of SMED: Understanding the Core Principles

- Internal Setup: All tasks that can be performed while the machine is still running, such as preparing tools and materials.

- External Setup: Any tasks that require the machine to be stopped, such as changing dies or fixtures.

- Conversion: The time it takes to transition from internal to external setup and vice versa.

- Setup Time: The total time required to complete both internal and external setup.

Unleashing the Benefits: The Transformative Impact of SMED

Implementing SMED unleashes a cascade of benefits that revolutionize manufacturing operations:

- Reduced Setup Times: SMED empowers manufacturers to slash setup times by up to 90%, maximizing machine utilization and increasing productivity.

- Enhanced Productivity: With reduced setup times, machines can spend more time producing, leading to significant productivity gains.

- Improved Quality: Reduced setup times minimize the risk of errors and defects, resulting in higher product quality.

- Reduced Inventory: SMED enables manufacturers to reduce inventory levels by making smaller batches more efficiently, improving cash flow and inventory management.

- Increased Flexibility: SMED enhances flexibility by allowing manufacturers to switch between products quickly, accommodating changing market demands.

Implementing SMED: A Step-by-Step Guide to Success

Embracing SMED requires a systematic approach, involving the following steps:

- Establish a Cross-Functional Team: Engage a team of engineers, operators, and supervisors to collaborate on the SMED implementation.

- Analyze the Existing Setup Process: Conduct a thorough analysis of the current setup process to identify areas for improvement.

- Separate Internal and External Setup: Distinguish between tasks that can and cannot be performed while the machine is running.

- Convert External to Internal Setup: Explore ways to convert as many external tasks as possible to internal tasks, reducing machine downtime.

- Streamline Internal Setup: Optimize the internal setup process by eliminating waste, standardizing tasks, and using ergonomic tools.

- Implement Quick-Change Fixtures: Employ quick-change fixtures and standardized tools to accelerate setup times.

- Train and Empower Employees: Provide comprehensive training to ensure that employees understand and can effectively implement the SMED system.

- Monitor and Continuously Improve: Regularly track performance, identify areas for further improvement, and make ongoing adjustments to optimize the SMED process.

Case Studies: Real-World Success Stories of SMED Implementation

Numerous manufacturers have successfully implemented SMED, achieving remarkable results:

- Toyota: The birthplace of SMED, Toyota has reduced setup times by over 90%, transforming its manufacturing operations and achieving exceptional productivity.

- Nike: Nike implemented SMED in its shoe manufacturing facilities, reducing setup times by 60%, increasing productivity by 20%, and improving product quality.

- Boeing: Boeing adopted SMED in its aircraft assembly operations, cutting setup times for major components by over 50%, resulting in significant cost savings and improved efficiency.

: Embracing the Revolution in Manufacturing

The SMED system is a transformative approach that revolutionizes manufacturing operations, unlocking unprecedented levels of efficiency, productivity, and flexibility. By embracing SMED's principles, manufacturers can gain a competitive edge, reduce costs, and deliver exceptional products that meet customer demands. Join the manufacturing revolution today and unlock the full potential of your operations with the SMED system.

4.7 out of 5

| Language | : | English |

| File size | : | 15309 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 371 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Elizabeth Ann Mcanally

Elizabeth Ann Mcanally Laura Charanza

Laura Charanza Michael Pembroke

Michael Pembroke Clive Barker

Clive Barker William J Weiner

William J Weiner Lauren M Dinour

Lauren M Dinour Philipp Teufel

Philipp Teufel Professor B D

Professor B D Jared Tendler

Jared Tendler Kalidasa Brown

Kalidasa Brown Michael Eigen

Michael Eigen Carter Lindberg

Carter Lindberg Gouverneur Morris

Gouverneur Morris Harold Boulette

Harold Boulette Peggy Jackson Walls

Peggy Jackson Walls Tracy Horntvedt

Tracy Horntvedt Kirsty Gallagher

Kirsty Gallagher William Richards

William Richards Michael J Grossman

Michael J Grossman Jessica Jones

Jessica Jones

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Kenneth ParkerCapture the Wonder: The Parents' Guide to Photographing Your Toddler and...

Kenneth ParkerCapture the Wonder: The Parents' Guide to Photographing Your Toddler and...

Brayden ReedFreemasonry and the Transformation of the American Social Order: Unveiling...

Brayden ReedFreemasonry and the Transformation of the American Social Order: Unveiling...

Avery SimmonsCritical History of Social Media: Uncovering the Roots and Repercussions of a...

Avery SimmonsCritical History of Social Media: Uncovering the Roots and Repercussions of a... Dan BrownFollow ·15.3k

Dan BrownFollow ·15.3k Robert HeinleinFollow ·5.9k

Robert HeinleinFollow ·5.9k Nick TurnerFollow ·13.3k

Nick TurnerFollow ·13.3k Bryan GrayFollow ·3k

Bryan GrayFollow ·3k Roland HayesFollow ·5.3k

Roland HayesFollow ·5.3k Easton PowellFollow ·12.6k

Easton PowellFollow ·12.6k Alex FosterFollow ·11.6k

Alex FosterFollow ·11.6k Braden WardFollow ·4.7k

Braden WardFollow ·4.7k

Henry Green

Henry GreenCorrosion and Its Consequences for Reinforced Concrete...

Corrosion is a major threat to reinforced...

James Gray

James GrayDiscover the Enigmatic World of Pascin in "Pascin Mega...

Immerse Yourself in the...

George R.R. Martin

George R.R. MartinUnlocking the Power of Nature: Delve into the Bioactive...

In a world increasingly...

Julian Powell

Julian PowellMaster the Art of Apple Watch App Development: A...

Unlock the Potential of Apple Watch Apps In...

Jaylen Mitchell

Jaylen MitchellPlastic Optical Fiber Sensors: A Comprehensive Guide to...

In the rapidly evolving landscape of...

Truman Capote

Truman CapoteUnlock the Secrets of Language Creation: Dive into...

The realm of computer science...

4.7 out of 5

| Language | : | English |

| File size | : | 15309 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 371 pages |